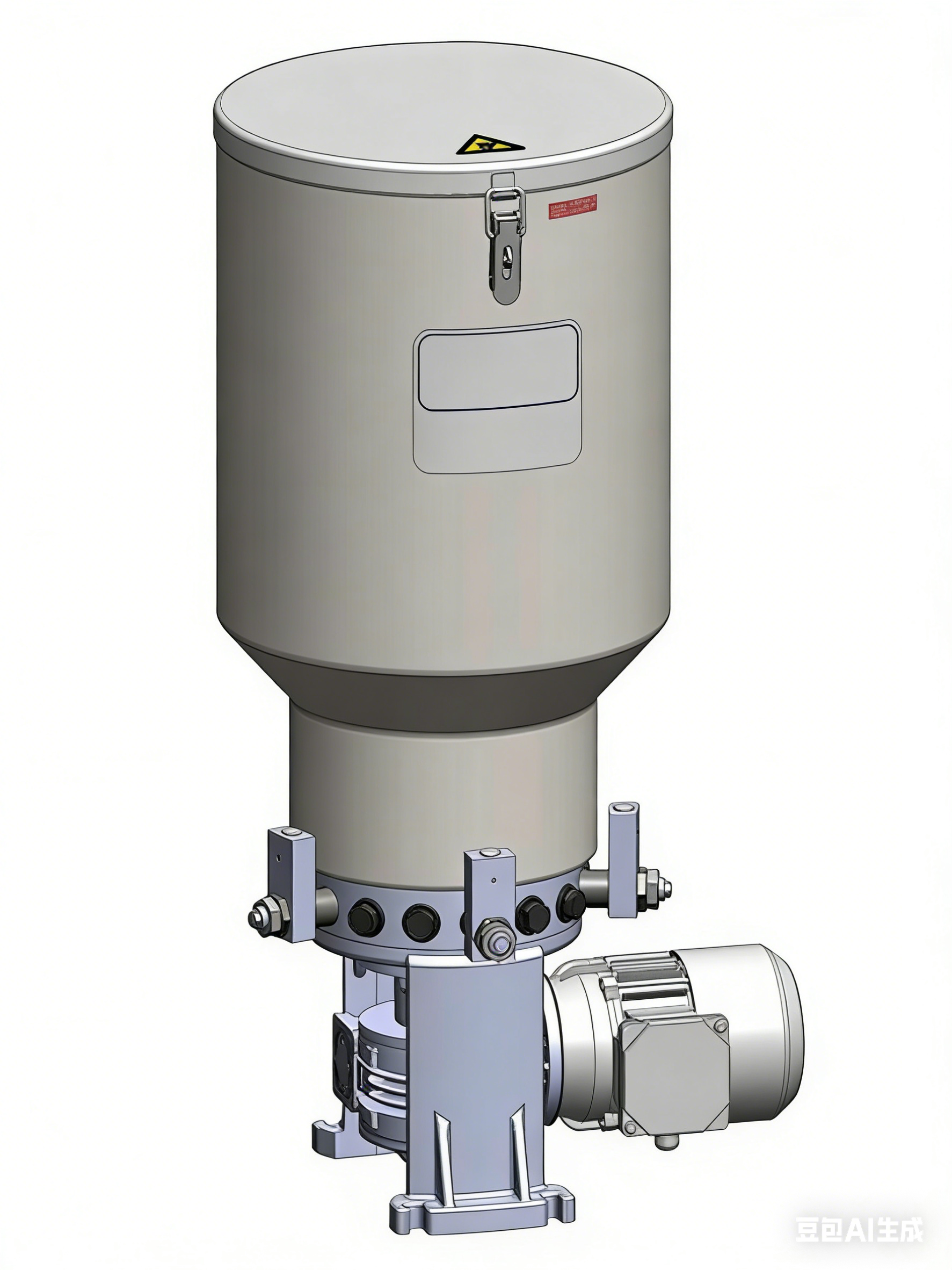

P 215- 15/30L -M10 electric lubrication pump for Multi-line automatic lubrication system with reservoir 15L 30L

mesolube Lubrication Pumps:

This high-pressure, multi-line pump can drive up to 15 elements. Different sizes of adjustable elements are available. It is capable of handling direct supply of lubrication points or can be used as a centralized lubrication pump in large-sized progressive systems.

P 215 pumps are available with a three-phase, multi-range motor, with a single-range motor, with a free shaft end for use with other motors, or with an oscillating drive. Various gear ratios and reservoirs of different sizes and materials are available. The reservoirs are suitable for both grease and oil and are offered with or without level control.

- These pumps P 215 lubrication pump feed lubricant from the reservoir into the tubing system of an automatic centralized lubrication system.

- They maintain sufficient pressure to compensate for pressure drops in tubing, filters, valves, distributors, and friction points.

- Different types include:

- multi-line lubrication systems

- Progressive lubrication systems

- Stationary machines with a high lubricant consumption

- Screens and crushers in quarries

- Material handling equipment

- Roller coasters

Description

For progressive lubrication systems

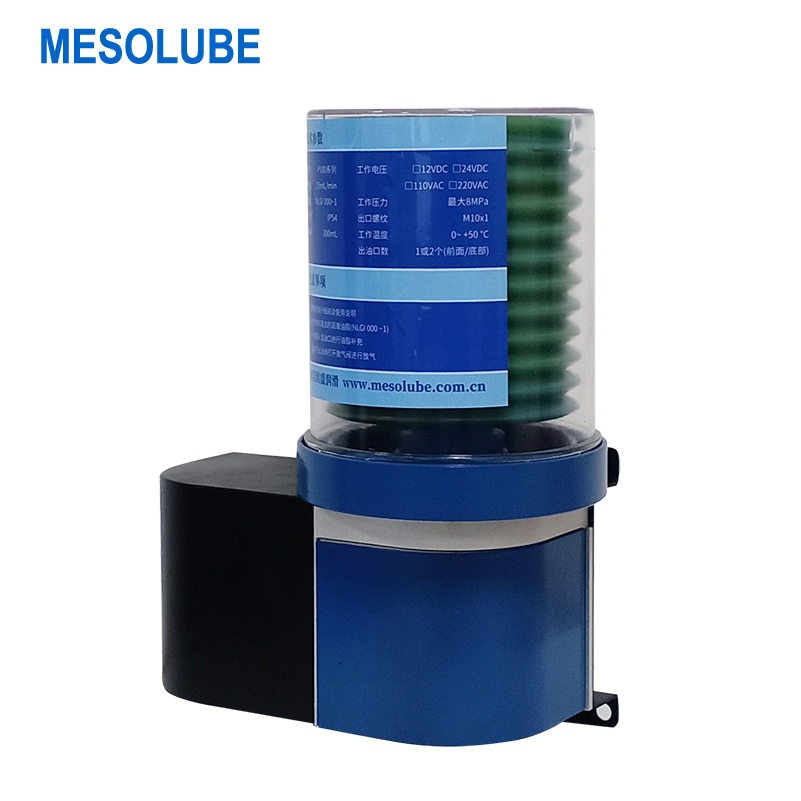

Tmesolube electic grease pump P304 are used in both single-line lubrication system or progressive lubrication system.we will provide all the lubricaiton products ,maintenance ,installation . there are suitable for many industrys ,including excavator ,wind power ,wheel truck ,loader , coal mine .cement and so on .how to choice a suitable lubrication system for your equipment .

under the following circumstance which lubricaiton system can be used ,

first .if every lubrication points need to different large quantities for every time ,

second ,there are unnecessary to be monitor each lubrication point,

third, the length of the main tubings are long even more than 50 meters . we advice that it is used single -line lubrication system.

Specifications

| Function principle | radial piston pump with stirrer; rotary, oscillating or electrically operated | |

| Outlets | 1 to 15 | |

| Operating temperature | –25 to +70 °C | -13 to +158 °F |

| Operating pressure | 350 bar | 5075 psi |

| Lubricant | mineral and synthetic oil and grease oil: viscosity from 20 mm²/s | |

| Metering quantity per stroke | min. 0,11 cm3 max. 0,23 cm3 |

0.0067 in3 0.014 in3 |

| Reservoir 1) | plastic: 4 and 8 kg | 8.8 and 17.6 lb |

| steel: 10, 30 and 100 kg | 22, 67 and 220 lb | |

| Internal ratio | 7:1, 49:1, 100:1, 490:1 | |

| Output per outlet | 0,13 to 6,4 cm³/min | 0.008 to 0.39 in³/min |

| Outlet connection | G 1/4 | |

| E-motor drive | with 3-phase motor | |

| Drive speed | <28 min-1 | |

| Dimensions | min. 438 × 453 × 326 mm max. 1 225 × 600 × 550 mm |

min. 17.24 × 17.84 × 12.84 in max. 48.23 × 23.26 × 21.65 in |

| Protection class | IP 55 | |

| Mounting position | vertical | |

| Options | hydraulic driven; 24 V DC motor | |

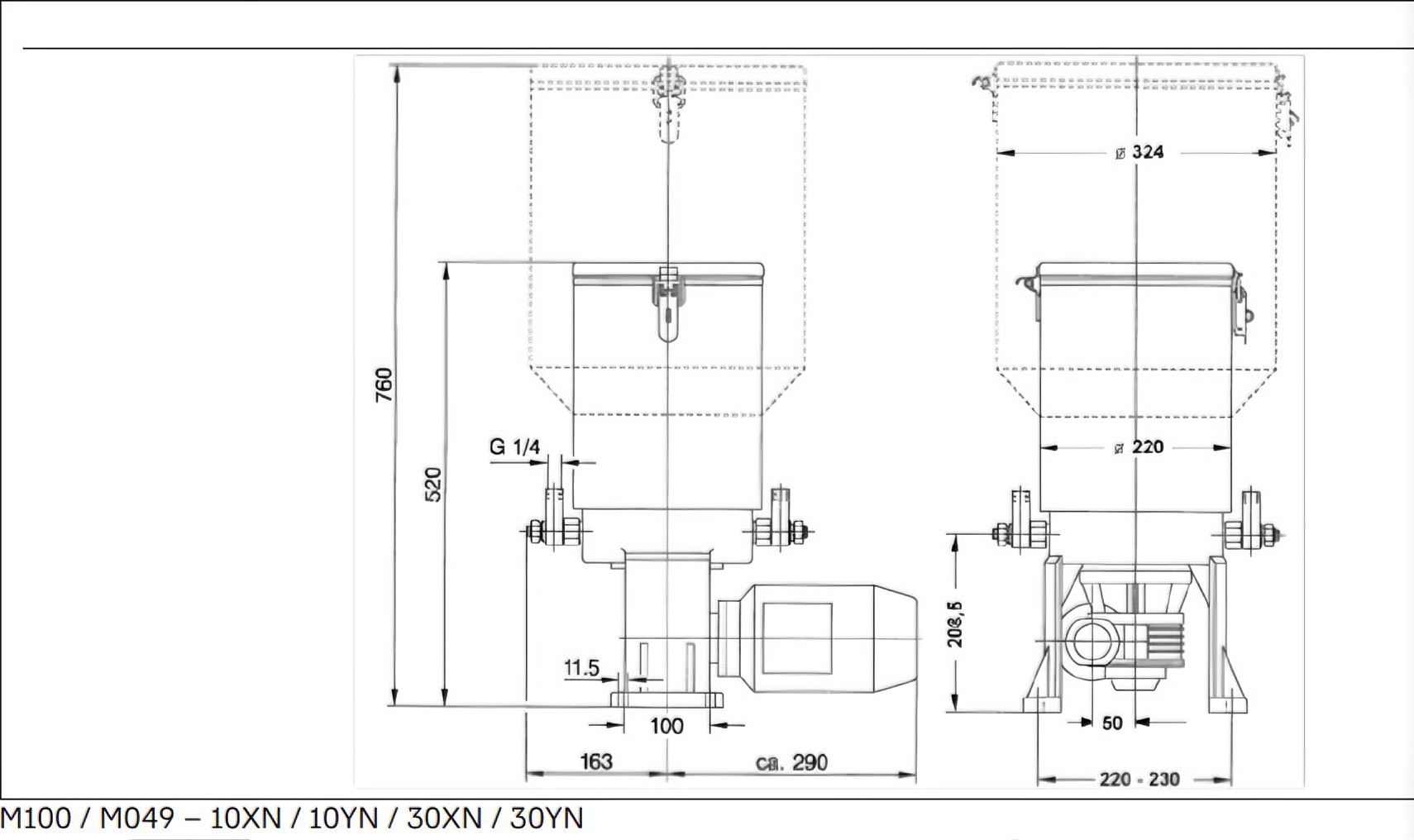

Dimensions

Please contact us for more dimensions!

Applications